ERP/MRP software, however, continuously calculates the direct material cost from purchases as well as the direct labor costs by summing up reported work hours of manufacturing orders. Conversely, indirect materials are generally used in many types of products in insignificant quantities per unit. These are not included in direct materials and fall into the manufacturing overhead. For example, for a furniture manufacturer, timber, paddings, and textile are the direct materials used in production, while glue or sandpaper are indirect materials. Before calculating the direct labour costs per unit you need to know how to calculate the direct hourly labour rate total manufacturing cost formula and direct labour hours. The total manufacturing cost formula can be used alongside your net revenue to work out how profitably your business is producing goods.

- This blog post will provide a comprehensive guide, providing a clear and step-by-step approach to calculating and interpreting total manufacturing costs effectively.

- Efficient supply chain management plays a crucial role in controlling manufacturing costs.

- For example, in car manufacturing, steel, tires, and glass are direct materials.

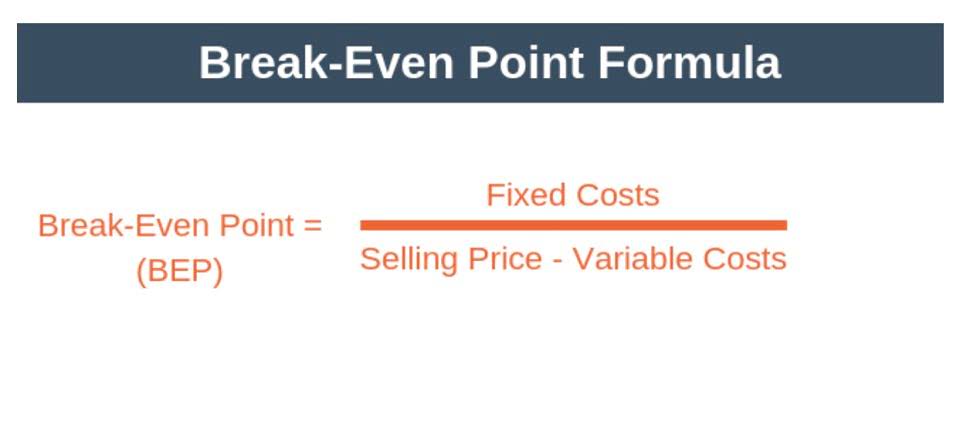

- Then, subtract the variable costs from the total and multiply it by the amount of product for the given production period.

- Common methods include Activity-Based Costing (ABC), which allocates costs based on activities performed, and traditional methods like allocating overhead based on direct labor hours.

Excluded from COGS:

Total manufacturing cost (TMC) also means total manufacturing cost, which is the total cost of all the activities to convert all the raw materials into a completed product. It is crucial in the business and reveals a certain order of the production processes in relation to the set objectives. Total manufacturing cost is an important metric for understanding a business’s overall expenses and profitability. This blog post will provide a comprehensive guide, providing a clear and step-by-step approach to calculating and interpreting total manufacturing costs effectively.

Use Timesheets to Monitor Labor Costs

- This covers expenses like utilities, factory maintenance, equipment depreciation, and the salaries of supervisors who oversee production.

- But remote access aside, Manufacturing software’s real strength comes from the fact that it unites all your business functions, allowing every employee to complete work within the same system.

- This means that unfinished products that were transferred into Work in Process (WIP) inventory are left out of the sum.

- Our software has powerful Gantt charts to plan your manufacturing costs and secure timesheets to track labor costs all in real time.

- Combining scientific literature with his easily digestible writing style, he shares his industry-findings by creating educational articles for manufacturing novices and experts alike.

Businesses can monitor and control manufacturing costs by setting up a robust cost tracking system, conducting regular budget vs. actual cost analyses, and identifying areas for improvement. An electronics manufacturer might routinely review material waste and implement measures to reduce it, leading to ongoing cost control. The Total Manufacturing Cost for one smartphone manufactured by ABC Electronics is $75. This cost encompasses all the expenses incurred directly and indirectly in the production process. Direct Labor Cost comprises the wages, salaries, and benefits paid to employees directly involved in the manufacturing process. These employees work directly on the production line and contribute directly to the creation of the goods.

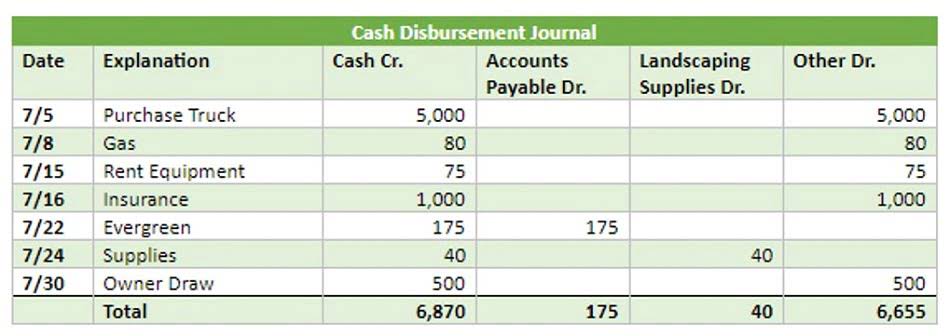

Example #3: Other direct costs

Businesses use different accounting methods to calculate COGS, affecting how inventory costs are recorded and reported. The choice of method can influence financial statements, tax liabilities, and profitability. The beginning inventory is the total value of goods available at the start of the accounting period. It includes Law Firm Accounts Receivable Management leftover stock from the previous period and can be found in the company’s balance sheet under inventory. From Cost accounting and Financial statements perspective, having a detailed product costing with a clearly defined cost structure for Finished products is important. Major cost components of manufacturing are machine equipment cost, energy costs, manufacturing expenses, administrative expenses and other hidden costs.

As the name indicates, these are the most recognizable elements that constitute the finished goods. Direct materials are the core components used in manufacturing finished goods. Examples include fabric for clothing, steel for automobiles, and wood for furniture. Manufacturing costs are recorded as assets (or inventory) in the company’s balance sheet until the finished goods are sold. A manufacturing company initially purchased individual components from different vendors and assembled them in-house.

This article aims to answer these questions in a simple, user-friendly manner, emphasizing five key aspects. This data is helpful in setting the lowest purchase price that will guarantee a profit after recovering such items as advertising, distributing, and administration expenses. A balance sheet is one of the financial statements that gives a view of the company’s financial position, while assets are the resources a company owns. To obtain these details, you can refer to the company’s employment records that has a list of all the employees and their hourly rates. After manufacturing product X, let’s say the company’s ending inventory (inventory left over) is $500.

Total petty cash Manufacturing Costs are a sum of all the expenses incurred from the initial stages of raw material acquisition to the final stage of delivering a finished product. This encompasses costs on direct materials, direct labor, and factory overheads. Calculating TMC is indispensable to ascertain the accurate cost of production, set competitive prices, identify inefficiencies, and strategize for cost reduction. The first step toward achieving these benefits is to know the different types of manufacturing costs. We’ve already identified manufacturing costs as direct material costs, direct labor costs and manufacturing overhead.

Add comment